Melt Units

The tank and unloaders primary responsibilities are to melt the adhesive and pump it to the required location through heated hoses. The tanks and unloaders also serve as the temperature sensing and controlling center for the gluing system. Most included a microprocessor control that monitors the temperatures and regulates them accordingly.

Pump options:

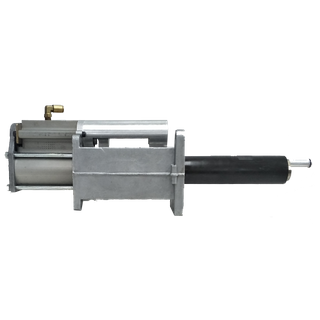

Piston Pump: The piston pump is used primarily in packaging applications. The piston pump provides high adhesive output as well as high pressures which are ideal in applications where multiple beads and valves are activated at the same time. Piston pumps are required for applications firing bottom up or in horizontal fashion as their high pressure output gives the best possible instantaneous glue output.

Gear Pump: The gear pump is used primarily in applications involving high viscosity adhesives and/or where there is a requirement for very controlled and metered adhesive output. However, they can also be used in low volume packaging applications where small volumes of adhesive are required. Gear pumps deliver adhesive at a very constant and consistent pressure, controllable with a "pressure relief valve" located on the back of each gear pump unit. Gear pumps can also provide line speed tracking without the use of an EPC when they are equipped with a variable speed motor drive which can increase or decrease pressure depending on parent machine speed.