IsoMelt and IsoMelt Plus Series

IsoMelt Series

PUR Adhesive Melter

Valco Melton's IsoMelt Series has been redesigned to achieve the highest melting rates in the industry. Although specifically designed to process reactive hot melts such as PUR, IsoMelt units allow for fast and easy changes to EVA or APAO without adhesive degradation. IsoMelt units can work with up to 40 liters of adhesive.

IsoMelt Series Benefits

- An improved melting grid design makes IsoMelt the units with the highest melting rate in the industry.

- Easy removal of adhesive residue allows switching between PUR and other types of adhesive.

- Ideally suited for any PUR applications, including those in the automotive, textile, product assembly, woodworking and PVC industries.

|

||

| IsoMelt Series Units | ||

| Tank Capacity | 40L | |

| Melting Capacity | PUR: Up to 35 Kg/h | EVA: Up to 50 Kg/h | |

| Max. Pumping Capacity per Pump | 90 kg/hr | |

| Number of Pumps | 2 | |

| Working Temperature Range | 15 - 230°C (59 - 446°F) | |

| Electrical Connection | 230 V 3-phase Δ / 400 V 3-phase Y – 50/60 Hz | |

| Max. Working Viscosity | 50 000 cps | |

| Max. Working Hydraulic Pressure | 80 bar | |

| Max. Electrical Tank Consumption | 7600 W single pump unit / 8700 W double pump unit | |

| Adhesives | PUR / EVA / APAO | |

| 4 Output Electronic Board | ||

| Max. Channel Power | Channel 1 / Channel 2 | Channel 3 / Channel 4 |

| Per channel (hose and gun) | 2000W | 1400W |

IsoMelt Plus Series

Melt On Demand PUR Adhesive Melters

Valco Melton's IsoMelt Plus Melters have been redesigned to better adapt to the changing needs of the industry. A new

touch-screen control panel guarantees a smooth communication with the parent machine, for a seamless in-line integration.

The combination of a new melting grid design and a larger reservoir tank results in a more efficient melting process.

IsoMelt Plus Series Benefits

- Melt on demand technology. Ideally suited to work with reactive adhesives, as it eliminates degradation problems by ensuring only the necessary amount of adhesive is melted every time.

- No need to manipulate PUR. Forget unwrapping, the adhesive goes directly to the melting tank.

- Hermetic sealing. When the cylinder presses the adhesive slug, the wrapping foil makes the tank hermetic, maintaining PUR properties without the need of using inert gas.

|

||

| IsoMelt Plus | ||

| PUR Slug Size | 20,0 kg | |

| Max. Melting Rate | 28 kg/hr | |

| Reservoir Tank Capacity | 3.7 L | |

| Max. Pump Rate per Pump | 48 kg/hr | |

| Max. Number of Pumps | 2 | |

| Max. Working Temperature | 240°C (446°F) | |

| Max. Working Viscosity | 50 000 cps | |

| Max. Working Pressure | 80 bar | |

| Electrical Consumption | 7600 W single pump unit / 8700 W double pump unit | |

| Tank Dimensions | 281 mm inner ø x 600 mm length | |

| Protection | IP54 | |

| 4 Output Electronic Board | ||

| Max. Channel Power | Channel 1 / Channel 2 | Channel 3 / Channel 4 |

| Per exit (hose and gun) | 1900W | |

| Per channel (hose or gun) | 1800W | 1400W |

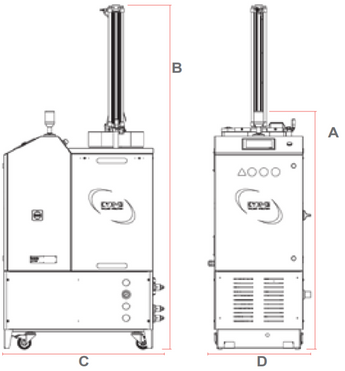

| Dimensions | ||

|

A | 1416mm (55.7") |

| B | 2044mm (80.5") | |

| C | 951mm (37.5") | |

| D | 610mm (24") |

|

IsoMelt and IsoMelt Plus Series Brochure |